Why Us

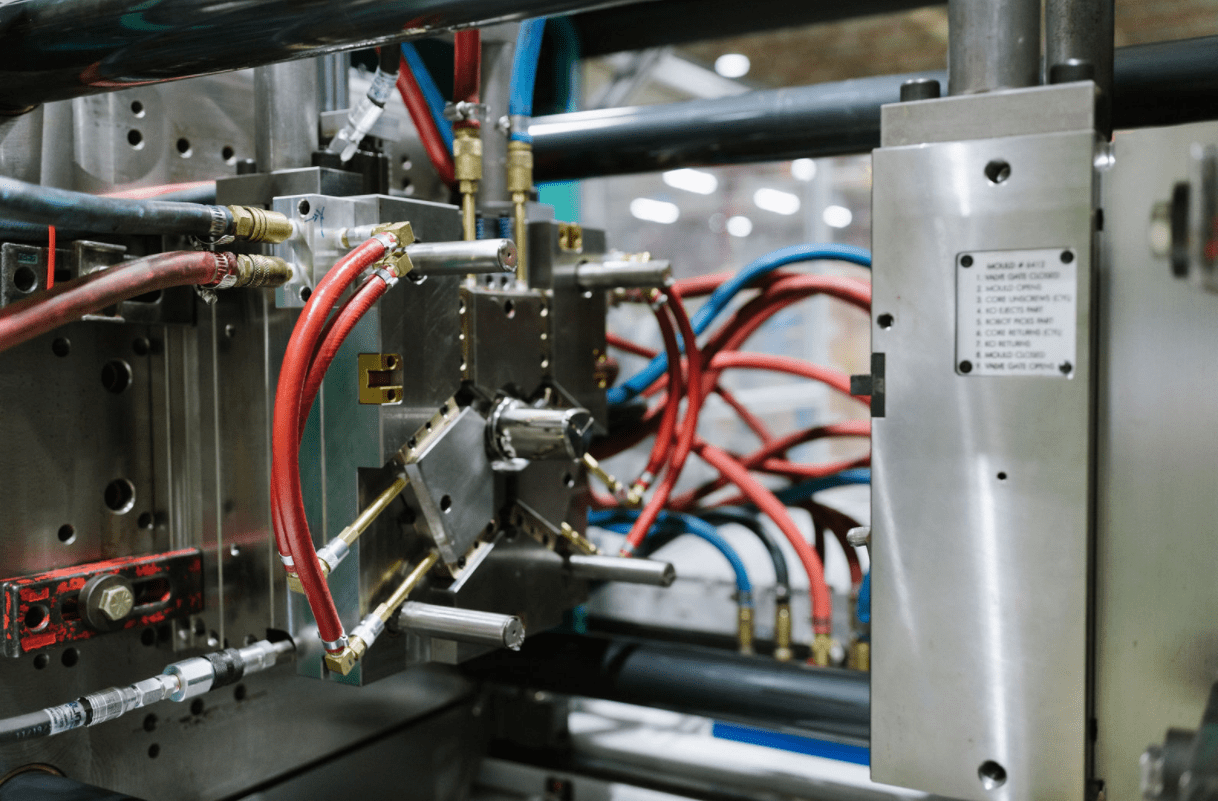

We’ve invested in state-of-the-art technology in our 50,000 square foot facility with ISO Class 7 Clean Room and in house tool room. More importantly, we’ve invested in the people with the experience, passion, knowhow and creativity to ensure your project is delivered exactly when and where you need it. We do everything in our power to keep you informed on every aspect of the process, so it is like working with a trusted friend. With us, it is a partnership and we will always be direct.

How We Work

Industries We Work With

Careers

Interested in a creatively challenging career with never a dull day and a rewarding, supportive culture? Good.